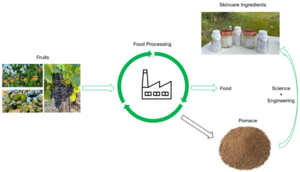

In a recent contribution, we discussed how the skin can acquire skincare actives from food materials (Food by skin: cosmetic actives from plants | in-cosmetics Connect). Now, let us examine how cosmetic ingredients can be sustainably obtained from the food processing industry without any negative impacts on food availability and while providing significant additional value to both the food and cosmetic industries.

The fruit processing industry has grown steadily over the last few decades to keep up with increasing demand for fruit products. Fruit processing produces large amounts of byproducts; these byproducts are normally used as animal feed or are discharged directly to the environment. When discharged, the byproducts generate environmental management burdens, and by not recovering the remaining antioxidants, major biological value is wasted.

There are significant bodies of research into the science and engineering of recovering functional compounds—such as polyphenols, proteins, and carotenoids—from food byproducts, particularly for high-valued applications such as skincare. Herein, we provide an overview of recovering bioactive compounds from fruit processing pomace and repurposing them as skincare ingredients.

Depending on the fruit, residues from fruit processing may contain high amounts of bioactive compounds, including dietary fiber, which makes these residues an attractive source of nutrients. Many health-promoting effects have been attributed to these bioactive compounds: these include reducing the risk of cardiovascular diseases and cancer through antioxidant and anti-inflammatory activities. Similar benefits have been reported when these compounds—for example, phenolic acids, flavonoids, and stilbenes—are incorporated as skincare active ingredients. Because many phenolic compounds are found in fruit skin and seeds, which make up the majority of pomace, fruit processing pomaces are promising sources of skincare ingredients with high antioxidant capacity, among other beneficial qualities.

Pomace is a byproduct of fruit juice production, which usually starts with washing the raw materials and removing foreign objects. Next, the fresh or frozen fruits are crushed into mash, and then the mash is heated to 40-50 °C. In many cases, the mash is next treated with depectinizing enzymes for approximately 1-3 hours; this causes cell wall structures to break down, disrupting the highly viscous pectin gel formed during mashing. As such, this enzyme treatment increases juice yield while allowing more polyphenols to be extracted. The juice is then separated from the solid cell materials using a mechanical press setup. Finally, the juice is cleared using disk stack or decanter centrifuges and then pasteurized to secure an appropriate shelf life.

The pomaces that remain after fruit extraction contain 50-80% moisture. Consequently, they are highly susceptible to microbial spoilage, especially by yeasts and molds. If these pomaces will be repurposed as skincare ingredients, it is essential to process them immediately and reduce their moisture levels. The timing and conditions of the drying process also significantly influence the characteristics of the pomace, such as its appearance, color, porosity, and types and amounts of bioactive compounds.

The subsequent step is to extract these bioactive compounds from pomace for skincare purposes; this process also significantly impacts the skincare efficacies of the resulting ingredient. Various extraction technologies are available: Conventional extraction uses heat with an organic solvent or water as the medium. More sophisticated approaches use alternative energy sources such as microwave, infrared, or ultrasound with nonconventional solvents such as supercritical carbon dioxide or ionic liquids.

Re-engineering fruit processing byproducts into skincare ingredients significantly increases the sustainability of the fruit processing chain by reusing material that is often considered waste. Pomaces can serve as natural alternatives to many conventional synthetic additives. In addition, the fruity flavors and interesting colors of pomaces provide opportunities for the development of new skincare ingredients with high antioxidative value. However, many challenges remain in fully utilizing all fruit processing byproducts. For example, in skincare applications, choosing the appropriate time and method with which to dry the pomace is key to maximizing the availability of all interesting molecules. Extensive process engineering is needed to optimize the extraction conditions and obtain the desired sensory and bioactive compounds for specific skincare objectives.

Enjoyed this article? Get more by subscribing to our newsletter!