Every artist uses color theory. By managing the amount and consistency of applied materials such as paint, clay, bronze, pastels, chalk, ink, etc., artists create their desired visual components. The ability to precisely overlap these elements is fundamental to an artist; it allows them to transmit their desired colors and effects to a canvas. Then they use their eyes to gauge and assess the results achieved.

Similarly, to enable optimum sunscreen performance, precise and consistent application of UV-protective ingredients to the skin surface is essential to shielding skin from UV radiation. However, while the naked eye can be used to monitor the amount and quality of a paint layer on canvas, the same eye cannot easily assess sunscreen performance. This is because most sunscreen ingredients that protect against UV radiation are not visible to the naked eye. UV-sensitive cameras have been used at times to enable humans to “see” UV active materials. However, UV cameras have failed to gain popularity in common consumer applications due to the inconvenience of carrying a camera only for seeing and applying sunscreen.

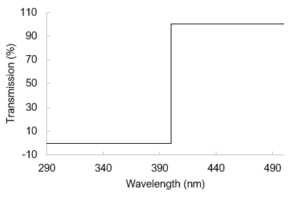

In a laboratory, the ability and quality of sunscreen layers in preventing UV light from transmitting can be precisely measured. The ideal sunscreen layer should allow no transmittance in the UV region that humans are exposed to on the earth’s surface (290-400nm). At the same time, it should immediately allow 100% transmittance at 400 nm and above (see Figure 1). This is because humans can see light with wavelengths longer than 400 nm; consequently, any materials interfering with light longer than 400 nm appear to have a color. A colored sunscreen is cosmetically unacceptable to most consumers.

Figure 1: Ideal transmission spectrum of a perfect sunscreen.

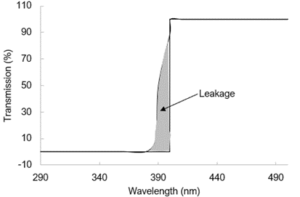

However, materials with an abrupt transmittance change from 0% to 100% at 400 nm (or any other wavelength) do not exist. The ability of a material to prevent light transmission is dependent on a collection of probabilities of its molecules’ interacting with photons. These probabilities do not change from 0% to 100% for all molecules at one wavelength. Therefore, even the best UV-protective materials can only achieve a transition of transmittance from 0% to 100% right before 400 nm (see Figure 2). The idea is to make this transition occur during as narrow a wavelength range as possible.

Figure 2: Best transmission spectrum of a sunscreen.

To ensure the product appears colorless to human eyes, the transition from 0% to 100% transmission needs to start before 400 nm in order to achieve 100% at 400 nm. The region between the wavelength where the transmission starts to increase and 400 nm makes up an unavoidable “leakage” area. In this “leakage” area, harmful UV photons are allowed to reach human skin.

Nature has a way to handle such unavoidable leakages. Chlorophylls in the thylakoid membrane of plant leaves harvest sunlight and convert the energy to sugars, making life on earth possible. Chlorophylls are abundant in plants and absorb mainly red and blue wavelengths; they reflect green light and therefore appear green to humans. The number one insult to plant photosynthesis is the sun itself. Due to unavoidable variations in sunlight intensity and wavelength, undesired irradiation sometimes reaches chlorophyll molecules, creating oxidative stresses. One of the approaches plants use to protect themselves against excessive sun irradiation is to produce antioxidants capable of capturing free radicals and electrons, thereby scavenging any leaked reactive oxygen species. These molecules and their mechanisms were detailed in an earlier article. https://connect.in-cosmetics.com/formulation/plant-antioxidants-mechanisms-and-properties/

Incorporating these antioxidative molecules into sunscreens effectively mitigates the unavoidable irradiation leakages presented by the UV-protective ingredients. There are multiple ways to incorporate antioxidative functions into sunscreen formulations. We will explain these strategies in future contributions.

Enjoyed this article? Get more by subscribing to our newsletter!

Feeling inspired to see ingredients and trends in action?

Then why not visit one of the in-cosmetics events around the world?