Compared to other types of personal care formulations, creating sunscreen formulas is not an easy task! There are considerable regulations to comply with, limits to the types and amounts of UV filters you can use, additional stability requirements for the sunscreen formula and ensuring SPF ratings are maintained. This blog explains how to create sunscreen formulas to get you started – and then it’s a matter of extensive sample development to get the end product just right.

Before you start formulating sunscreens…

The first thing you need to do is check whether sunscreen products are regulated as cosmetics or drugs in your region. There are also additional rules over ‘water resistance’ claims, warnings and certain label information required with all sunscreen products. Before you place a sunscreen product onto the market, make sure your brand has checked essential compliance requirements and conducts their own SPF testing specific to their sunscreen formula.

You can also find out more with our video: Should your cosmetic brand have a sunscreen product?

Be careful of sunscreen formula myths! Read this blog to be informed of common sunscreen formula myths and the truth behind them.

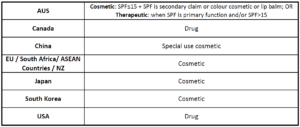

Here is an overview of how different countries regular products with SPF claims:

Choosing the sunscreen agents: organic vs inorganic UV filters

There are two types of sunscreen agents:

- Organic Sunscreens:

- commonly referred to as chemical sunscreen agents, they work by absorbing UV light.

- conform to organic chemistry principles but are NOT permitted in natural or organic sunscreen formulas.

- common examples: ethylhexyl methoxycinnamate (also known as octyl methoxycinnamate); benzophenone-3, ethylhexyl salicylate and homosalate.

- Inorganic Sunscreens:

- commonly referred to as natural or physical sunscreen agents; they work by reflecting or scattering UV light.

- conform to inorganic chemistry principles but ARE permitted in natural and organic sunscreen formulas (even though they are NOT actually all natural).

- common examples: zinc oxide and titanium oxide.

Why do sunscreen formulas typically contain a combination of UV filters?

The combination of organic and inorganic sunscreen agents is used in many sunscreen formulas because a blend can help achieve a higher SPF and UVA rating, a broad-spectrum rating, and improvements to skin feel and sunscreen formulation stability. UV filters are very specific with the wavelengths of light in the UVA or UVB spectrum over which they are effective. To be considered ‘broad spectrum’, a sunscreen formula must contain sufficient coverage over a large amount of the UVA and UVB spectrum (from 290 – 400nm).

There are also regulatory limits over the types and amounts of sunscreen agents that can be used in a sunscreen formula. This means you can’t usually achieve the required SPF without combining at least a few sunscreen agents.

Sunscreen formulas: get the base right!

Even if you have a great combination of UV filters in a sunscreen formula, the SPF performance will be affected by:

- the way the product spreads: a smooth, even film on the skin provides the best SPF rating.

- product stability: if the base formula starts to separate or form lumps over time, application will not enable an even spread of the sunscreen ingredients.

- compatibility: UV agents cannot be allowed to agglomerate or crystallise over time.

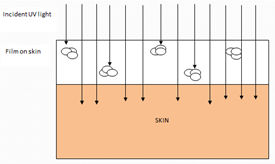

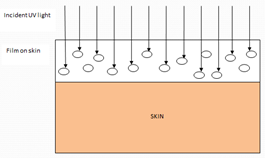

Consider these images:

Both diagrams use the same quantity of incidental UV light (represented by the arrows) and UV filters (represented by the ovals). The image on the left provides an example of when UV filters agglomorate, resulting in a low SPF. The image on the right shows an even spread, to catch the most incidental UV light, which would yield a much higher SPF.

Step-by-step: how to create sunscreen formulas

Formulating sunscreens is not like formulating other personal care products. You will need to follow the steps below to create a sunscreen formula in theory, and then create samples, carefully evaluate, and amend your formula several times before you can get it just right and test the final product to confirm the required SPF results are obtained.

- Determine UV filters and input amounts required to achieve the required SPF (in theory)

- Check all inputs comply with local country regulations and provide broad spectrum UV protection.

- Determine suitable lipids to ensure compatibility and even spread of the UV filters.

- Add the lipid soluble UV filter input + selected lipids to determine the total lipid input. This will determine if your formula is likely to be w/o or o/w. Note: most sunscreens with high SPF are w/o or w/si emulsions because there is typically a high lipid/lipid soluble component needed to get a good spread and high SPF rating.

- Select the emulsifiers + polymers to stabilise the UV filters and suit the formulation type.

- Check all inputs comply with local country regulations and are compatible with the selected sunscreen ingredients.

- Add compatible film formers for water resistance.

- Double check the formula for stability and compatibility, remembering a stable formula with good spread helps yield the best possible SPF.

Then you are ready to source your materials and start preparing samples!

Watch these videos to see further guidance and sunscreen formulas:

- How to make a SPF50+ sunscreen formula

- How to make a natural sunscreen formula

- Clear sunscreen gel formula with glitter

- How to make zinc stick SPF30+

- How to make clear sunscreen stick SPF25

- SPF boosters – boost the SPF of your sunscreen formulas

- How to make organic SPF15 serum

Happy formulating!

Enjoyed this article? Get more by subscribing to our newsletter!

Feeling inspired to see ingredients and trends in action?

Then why not visit one of the in-cosmetics events around the world?