by: Cargill

As one of the global leaders in nature-derived personal care ingredients, Cargill Beauty has built extensive experience in the sourcing, production and application of carrageenans in the past years. After successfully introducing Lambda and Iota carrageenan, Cargill Beauty is now completing its carrageenan portfolio with the addition of Satiagel™ VPC 614, a Kappa carrageenan, specifically suitable for high gelling applications and solid formulations.

Consumers are increasingly looking for more natural cosmetic products with cleaner labels. At the same time, they don’t want their products to compromise on functionality or performance. To be able to meet these evolving consumer needs, personal care manufacturers need to (re-)formulate and find a balance between naturality, functionality and great sensory. With Cargill Beauty’s complete set of carrageenans, the industry now has a solution that ticks all the boxes.

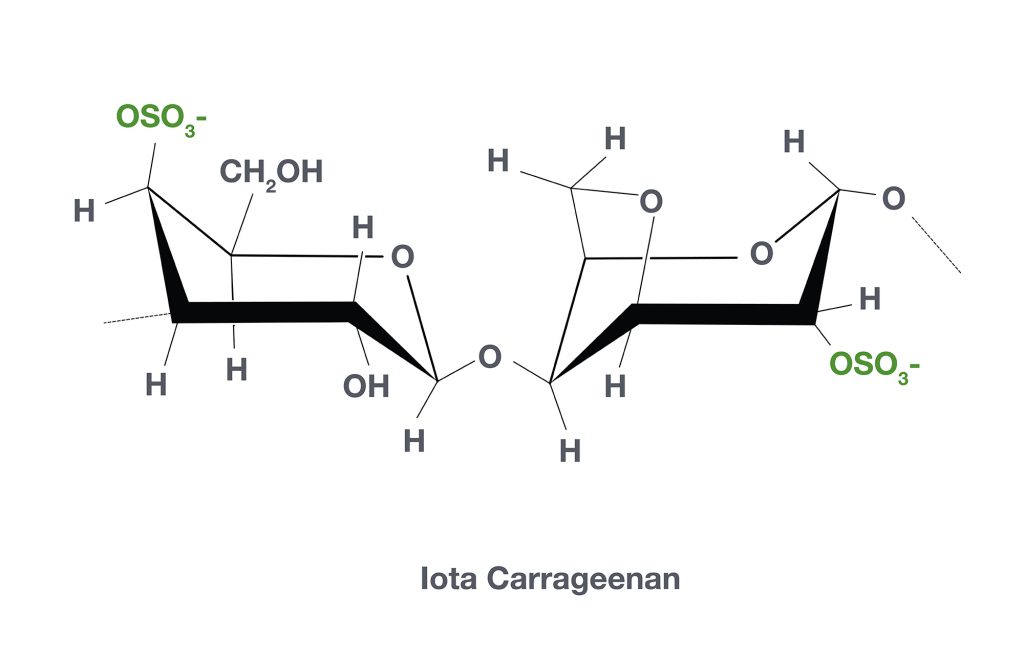

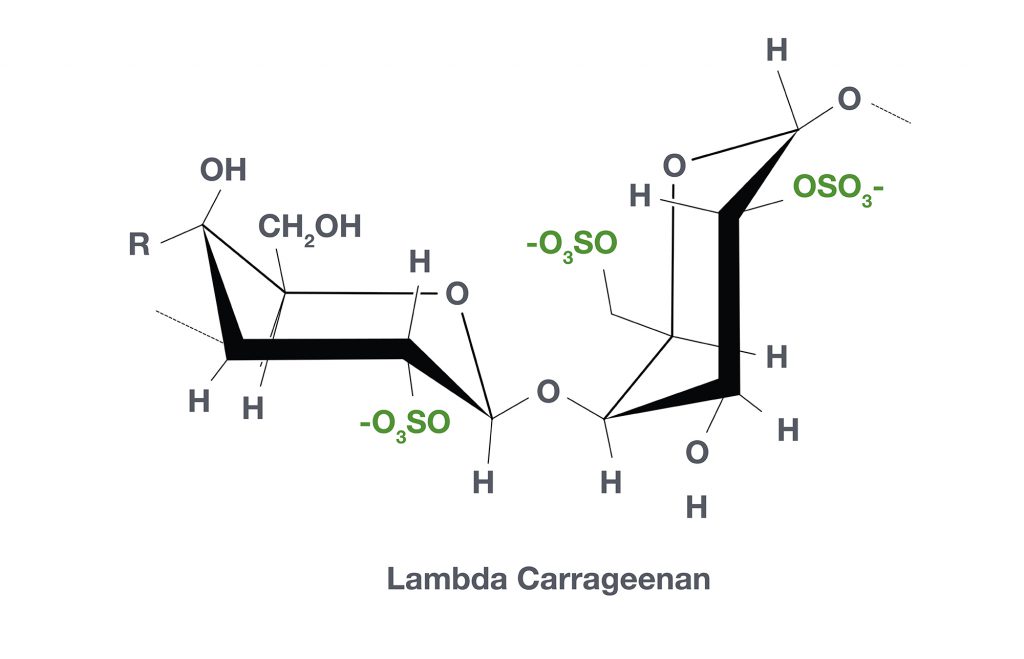

Let’s take a deep dive into the ocean of opportunity that carrageenans provide. Carrageenans are a family of natural linear sulfated polysaccharides that are extracted from red seaweeds. They are widely used in the personal care industry, for their gelling, thickening, and stabilizing properties. Carrageenans are classified in three main types of molecules: kappa, iota and lambda, varying on the number of sulfates present in the polysaccharide chain. Kappa and Iota respectively have 1 and 2 Cargill beauty news launch satiagel kappa carrageenansulphate groups, with one anhydro-galactose bridge. Lambda has 3 sulphate groups.

This difference on the chemical structure will determine if the carrageenan will have more of a thickening or gelling behavior. Kappa and Iota carrageenans can give gel structures thus are known as gelling carrageenans, while lambda is a thickening carrageenan.

Once carrageenan is solubilized in water, the gelling mechanism initiates with the formation of α-helix zones or spiral-like associations in molecules. Further, single helices arrange with adjacent ones to form double-helical structures with electrolyte addition. The negative charges (sulfate groups) are all orientated to the external side of the helix. Once the K+ cation is added, all the double helixes will associate with each other (creating a link between the SO3- and the K+).

For Kappa carrageenan, the solubilization temperature is 60-70°C. However, a combination of time/temperature/ shear also plays a role. Gelation of Kappa carrageenan is particularly enhanced by the addition of potassium ion. It induces gel formation at very low concentrations. Because of its small hydro-dynamic size when hydrated, the potassium ion fits into the coil and partially neutralizes the sulfate groups. Thus, the double-helices can cluster together and form aggregates that create a strong & brittle gel with a short texture. The gels are thermoreversible and do not exhibit thixotropic behavior like Iota and Lambda carrageenan.

For Iota carrageenan, the solubilization temperature is 50-60°C. Iota has more charges than Kappa, thus it is easier to solubilize Iota than Kappa. The Iota molecules also arrange themselves in double helixes. But the structure of all the helixes is more in the shape of a star because it has much more negative charges on the external sides of the helixes (more electro repulsions leaves more space between all the helixes which results in a more lose network). Iota exhibits thixotropic behavior and is suitable to get a nice elastic gel network.

For Lambda carrageenan, heat is not required to solubilize, as it is cold-water-soluble. This makes it well suited in personal care applications where no heat processing is desired. Lambda carrageenan gives thickened solutions and imparts viscosity in aqueous phase. A high number of sulfate group inhibit the 3D network formation due to the strong repulsion of sulfate groups thus a thickened solution is obtained and not a gel.

Carrageenans are very versatile molecules and Kappa, Iota and Lambda provide a range of textures, viscosity, gelling and thickening properties that formulators can take advantage of in creating various product textures. And, because the different types all have the same INCI reference, they can help personal care manufacturers to keep their labels minimal. Carrageenans can be formulated in skincare products like serums, gels, emulsions, creams, lotions, toners. In skin cleansing products like face wash, body wash, shaving gels, face masks. In hair care products like shampoos, conditioners and hairstyling gel. Carrageenans are also widely used in oral care products like toothpaste and mouthwash.

Sustainability

Cargill launches satiagel kappa carrageenanTo help ensure a long-term sustainable red seaweed supply chain, Cargill has launched the Red Seaweed Promise™ in 2018. The program is specifically designed to address key sustainability challenges for the harvesting and cultivation of red seaweed, while enhancing producer livelihoods, supporting local communities and conserving the marine environment. The program also answers industry and consumers’ needs for more sustainable ingredients, with a commitment to source 60 per cent sustainable red seaweed by 2025.

Red seaweed production is critical to the prosperity of approximately one million producers and their communities. Today, these producers face multiple challenges, from climate change and extreme weather events to inefficient farming and harvesting practices, which have a significant impact on the quality of red seaweed. The Red Seaweed Promise supports producers’ prosperity by providing the training, coaching and tools producers need to adopt environmental and safe production best practices while committing to sustainable marine and coastal ecosystems.

The Red Seaweed Promise leverages Cargill’s strong partnerships with producers and suppliers to increase traceability and transparency in the supply chain for its customers. Proforest, a leading non-profit group offering consultancy services in sustainable sourcing of natural resources, supported Cargill in the definition of a credible industry-standard evaluation tool and conducted verifications in the regions where the company sources red seaweed. Results are used to set region-specific continuous improvement plans, focusing efforts on four priority areas: empowering seaweed producers, improving production and harvest practices, supporting sourcing communities and strengthening partnerships.