Like cosmetics, the primary function of paint is to protect and beautify the surfaces on which it is applied. Over the last 60 years, there have been two noticeable revolutions in the paint industry:

- The invention of latex paints that can be cleaned up with water yet become water-resistant when dried, creating long-lasting paint products that are easy and safe to apply.

- The invention of electrodeposition (ED) coatings that provide total and uniform coverage to all types of metal surfaces, practically eliminating car corrosion. The ED process has made car bodies last longer than car engines. Before ED, in places where lots of road salt were used to combat snow and ice, one often saw perfectly running cars with rusting and crumbling bodies.

The same types of revolutions are poised to happen in the beauty and personal care industry.

While emulsion technology has often been used in the cosmetic industry, much of the attention up to now has been focused on how to construct a good cosmetic formulation. There is not enough research and expertise regarding what happens to the emulsion product when it is taken out of the bottle and applied on human skin.

For the painting process, making a good paint in a can is only about halfway to a perfect paint job. Watching the paint dry – the physical and chemical engineering of the paint drying process – is critical to achieving the ideal performance and consumer perception of the paint product. Similarly, better understanding and methodically engineering the “drying” process of an emulsion cosmetic product from the moment it touches the skin to its removal from the skin surface will complete the other half of the skin beautification process. A comprehensive implementation of the emulsion sciences in both the construction of cosmetic products and their entire on-skin experience will bring profound changes to the landscapes of the beauty and personal care industry.

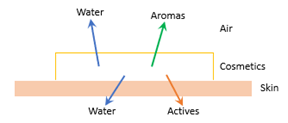

With the right ingredient chemistry and formulation skills, one can design a cosmetic product that provides the ideal amount of moisture (water to skin as shown above) to the skin over the entire period when the product is on the skin. When the speed and degree of water evaporation (water to air as shown above) is regulated by different phase and structure management, which is, in turn, enabled by appropriate emulsion organization, the concentrations and compatibilities of aroma ingredients and active ingredients are controlled. The ingredients are situated on the skin for the desired period time and are released at the desired rates, which enables long lasting performance and avoids potential skin irritations due to over concentration. Designing the right mechanics for the “drying” process of cosmetics on the skin also provides the ability to produce different skin feels. Skin sensorial performance is critical to consumer acceptance, particularly in Asia and Europe.

Electrodeposition processes revolutionized the coating industry by providing very uniform coating thicknesses, even on complex fabricated objects with sophisticated surfaces. Human skin is a complex surface with sophisticated topology. While it is unlikely that we will use electric currents to deliver a cosmetic product to our skin, the same engineering principles used in ED can be adopted to design cosmetics that “dry” with ED-type uniformity and homogeneity, as shown below.

The rheology and viscoelasticity of the “drying” cosmetic product are the driving forces behind a uniform and homogenous layer throughout its lifetime of normally 0 to 24 hours. Sophisticated engineering of emulsifier and emollient molecules and their alignments is essential to achieving the ideal rheology and viscoelasticity profiles throughout the entire dynamic process, which begins the moment the cosmetic touches the skin and ends the moment it is washed off. While this looks like a daunting task, many species in nature have managed to achieve this sort of responsive performance by evolving and adapting to their environments.

The ingenuity of cosmetic ingredient professionals will be put to the test to achieve these objectives. In addition to thoroughly understanding the “drying” process of cosmetics on the skin, we need to devise technologies that are “mild” and “skin-compatible”, which are essential to their commercial viability due to the live and sensitive nature of human skin.

Like the often unrecognized excitement of watching paint dry, sensing cosmetics is much more than what meets our eyes and noses. By drawing insight from the paint industry, we can create pleasant and performant cosmetics with nature-inspired technologies.

Enjoyed this article? Get more by subscribing to our newsletter!

Feeling inspired to see ingredients and trends in action?

Then why not visit one of the in-cosmetics events around the world?